Thunderbird Mine

Figure A: Project Location

Thunderbird Mineral Sand Project is in the Kimberley region in northern Western Australia on the Dampier Peninsula and lies 70 km west of Derby and 30 km north of the sealed Great Northern Highway (GNH) joining Derby and Broome.

Thunderbird is the first significant heavy mineral sand deposit to be discovered in the Canning Basin and is one of the largest and highest-grade mineral sands deposits globally, including those currently in production. The deposit, hosted by highly weathered Broome Sandstone contains valuable heavy minerals including ilmenite, zircon, leucoxene, rutile and anatase.

Figure B: Continuous Mining & Rehabilitation Process

The mineralisation is in a thick, broad anticlinal sheet like body striking northwest, folded from flat dip to a dip of about four degrees, extending under cover to the southwest. The areal extent, width, grade, geological continuity and grainsize of the Thunderbird mineralisation are interpreted to indicate an offshore, sub-wave base depositional environment, similar to the interpreted depositional environment of the WIM 150 deposit of the Murray Basin in south- eastern Australia.

Thunderbird has progressed from an exploration project to a substantial development project with significance to the local region and the State of Western Australia (State). The Sheffield campaign resulted in the Company declaring a large high-grade maiden Mineral Resource for the Thunderbird deposit on 18 December 2012.

Sheffield completed a Scoping Study in 2014 and Pre-Feasibility Study and PFS Update in 2015, leading to the announcement of a maiden Ore Reserve in January 2016. A Bankable Feasibility Study on Thunderbird was completed in March 2017 demonstrating the Project could produce and market high-quality zircon and ilmenite products at large volumes near to Asian markets.

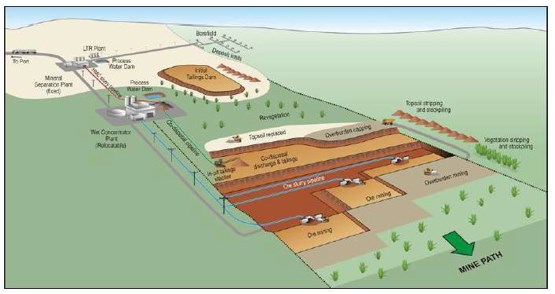

The 2017 BFS described a typical mineral sand mining operation where a moving void extracts the valuable mineral sands, with waste materials returned to the void enabling progressive rehabilitation of the mined area. Topsoil and overburden are excavated and transported using truck and excavator. Ore is excavated, screened, slurried and then pumped to a nearby wet concentration plant. Retaining cells are constructed in the developed mine void for the return of process tails. Topsoil is returned in a continuous rehabilitation process.

Minimal pre-strip is required to access the orebody as initial mining is concentrated in an area of ore occurring near surface. As the mining void is established, increasing amounts of overburden are mined and directly returned to the mining void as backfill.

In January 2021, Sheffield and Yansteel executed binding agreements for the formation of a 50:50 Joint Venture (Kimberley Mineral Sands Pty Ltd or ‘KMS’) to own and develop the Thunderbird Mineral Sands Project (Thunderbird) and adjacent tenements on the Dampier Peninsula. The parties have agreed that the development concept for Stage 1 of the Project will be a 10.4mt per annum mine and process plant producing a zircon rich non-magnetic concentrate and LTR ilmenite.

In March 2022, Kimberley Mineral Sands completed a revised Bankable Feasibility Study (KMS BFS), aligned with the joint venture requirements. The KMS BFS flowsheet is forecast to produce three products, a Non-Magnetic Concentrate product containing zircon and rutile, an ilmenite rich Magnetic Concentrate and a Paramagnetic Concentrate. KMS has executed a binding offtake agreement for 100% of the magnetic concentrate with joint venture and ilmenite offtake partner Yansteel. Construction of a vertically integrated complex in Tangshan, China is underway by Yansteel.

The two stage Thunderbird development pathway sees the initial Stage 1 mining and processing feed rate forecast at 1,085 dry tph at the Wet Concentrate Plant (WCP), with Stage 2 doubling the WCP feed rate to 2,170tph targeted during Year 5 of operations. Stage 1 and 2 of operations is estimated to produce 1.4mtpa of zircon and ilmenite concentrates over an estimated 36 year Life of Mine. Ongoing supply shortages within mineral sands markets is resulting in strong demand for Thunderbird products, with approximately 80% of the KMS BFS Stage 1 revenues contracted under binding, long term offtake agreements.

The Project includes the Night Train deposit, 20km to the east of Thunderbird, with an Inferred Mineral Resource of 130Mt @ 3.3% HM and a further 14 zones of significant mineralisation along a 160km long highly mineralised trend.

Night Train

The Night Train prospect is located 20km south of Thunderbird. Mineralisation has been defined on one main line of drilling and is open in most directions.

At 1% HM cut-off the mineralisation is 1.6km wide and from 4.5m to 24m thick (average 11m), with an average HM grade of 4.04%. At 3% HM cut-off, mineralisation is 1.0km wide, from 3m to 12m thick (average 7.5m), with an average grade of 6.40% HM.

Night Train has a high value mineral assemblage with 92% VHM, comprising 15% zircon, 53% leucoxene, 8% HiTi leucoxene and 16% ilmenite. The heavy mineral is free from coatings and has a very high zircon content. The mineralisation is hosted by fine, clean, predominantly quartz sand.

Night Train is located just 2km from the proposed Thunderbird Project haul road or 20 km south east of the proposed Thunderbird process plant. This substantial new discovery is further evidence of Sheffield’s prime position in the emerging Canning Basin mineral sands province.